Ensure an efficient and safe mining transportation

Transportation

The distance between the material extraction site and the processing plant is constantly growing. Innomotics Conveyors helps you cover long distances and, simultaneously, increase your transported load and process speed – while also saving you energy and money along with providing a high level of employee safety and equipment protection.

Maximum power for maximum transport profitability and safety

Innomotics solutions for mining transportation

No matter if the ore is close to the processing plant or in more and more remote areas, reliable and safe transportation solutions are always required.

Moving mountains reliably and efficiently

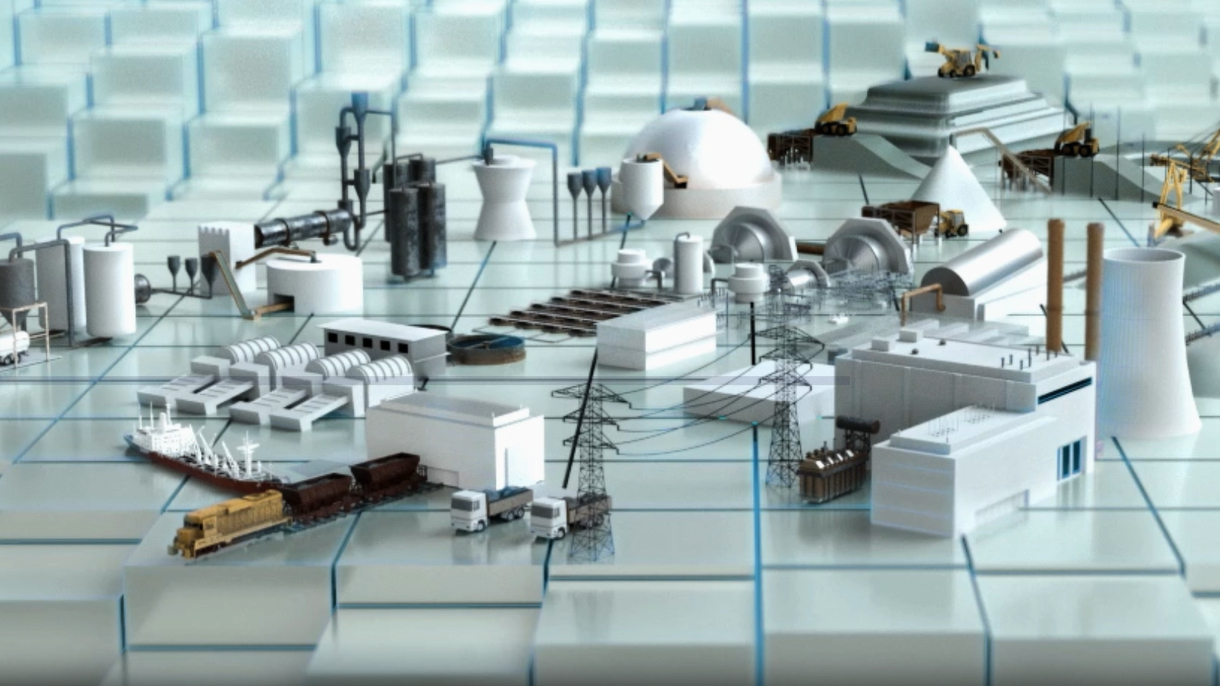

Safe and efficient transport of material is top priority for both underground and open-pit mines. The bulk material has to be transported quickly, while regarding energy use. Hence, energy-efficient solutions are mandatory to operate most cost- effectively. With our solutions for trucks and trolleys, conveyor systems, mine winders, and mining material handling you can easily meet the transportation challenges of today and tomorrow – thanks to a higher degree of operational safety and reliability, lower operating costs, increased productivity and energy savings as well, as drastically reduced exhaust and noise emissions.

Innomotics portfolio for mining transportation

Conveyor systems

To meet worldwide demands for raw materials, you have to move billions of tons of rock – powerfully, reliably, and efficiently. This makes conveyor solutions business-critical, especially regarding their performance and availability. To operate efficiently, it is essential that belt conveyors remain failure-free – a factor that in turn depends on high availability and reliability.

With Innomotics Conveyor, you can count on high system availability as well as low operating, energy, and maintenance costs. Integrated solutions from Innomotics for belt conveyor systems consist of powerful mechanics and motors, variable-speed drives as well as durable geared drives or highly efficient gearless drive systems. And we are one of only few international companies with sufficient know-how to combine all relevant components into a truly integrated overall concept.

Mine winder technology

Underground mining depends critically on the capability, reliability, and safety of the hoisting equipment. Increase output while boosting the safety of those in the shaft: Innomotics Winder assures the highest levels of safety coupled with maximum performance thanks to innovative solutions for drive engineering, performance-optimizing drive-level closed-loop controls, and safety-oriented automation engineering.

We use our expertise to develop and implement exactly the right drive system for your mine – adapted to the conditions of the power supply system and tailored to your power rectifier “philosophy”. Our technological closed-loop controls ensure the harmonious customization of travel behavior to the specific requirements of your shaft system.

Mining trucks

Innomotics Mobile Mining provides diesel-electric and trolley-powered drive systems suitable for haul trucks that are used in open-pit and underground mines. Our portfolio contains hardware and software solutions as well as drive systems for 280 to 400 short ton surface mine trucks.

Innomotics (former Siemens* Large Drives) started to develop and produce e-drive systems for haul trucks at the beginning of the nineties. Since that time we have been one of the key suppliers in the global mining truck market. Moreover, we have consequently and continuously improved and extended our portfolio which we call Innomotics truck. Today we offer innovative and reliable drive systems to suit the individual requirements of our partners: the mine operators and the OEMs.

Bulk material handling

These days, “mining material handling” means the material management of raw materials. The main task is to make the required amount of raw materials available in the required quality at the specified time. Innomotics Bulk material handling has solutions for: drive technology, automation, energy supply, sensor technology, and much more.

With Innomotics solutions, we support:

- High plant availability

- Reduction of operating and energy costs

- Lower maintenance and repair costs

And we are one of the few international companies with sufficient know-how to combine all the relevant components into a truly integrated overall concept.

Innomotics DigiMine YardMaster

More control over your entire stockyard

When it comes to stockyards, nothing matters more than stockyard management. As raw materials become an increasingly important element for the development of new technologies, it's crucial that our clients are prepared with the best digital solutions to face the challenges of a sustainable, renewable, and changing future. DigiMine YardMaster is developed to eliminate inefficiencies, prevent wrong decisions, and – most of all – benefit your entire operation. By incorporating autonomous machine operation, source to destination tracking, and intelligent planning, DigiMine YardMaster is a digital solution that gives clients complete control of their stockyard. With three independent modules, you can fully monitor and supervise high-value machinery and resources.

References - Examples of excellence in mining transportation

LUMWANA COPPER MINE, ZAMBIA

Truck and trolley system for African mine

- Innomotics (former Siemens Large Drives) delivered equipment for 27 open-pit mining trucks and two ore mills with corresponding infrastructure.

- Thanks to our diesel-electric drive concept, the trucks’ environmental compatibility increased by 11.6 % and the operating costs decreased by 7 %.

- Reduce the consumption of diesel during overburden removal and mining of copper ore.

ANTAPACCAY COPPER MINE, PERU

Gearless conveyor solution at 4,200 m ASL

- Innomotics (former Siemens Large Drives) supplied and commissioned direct-drive systems for belt conveyor and grinding mills located 4,200 meters above sea level.

- The motor size is not limited by the gearbox size, thus eliminating the need for multi-motor drives.

- Eliminating a whole series of mechanical and electrical components increases overall system reliability and efficiency by 3 to 4 %.