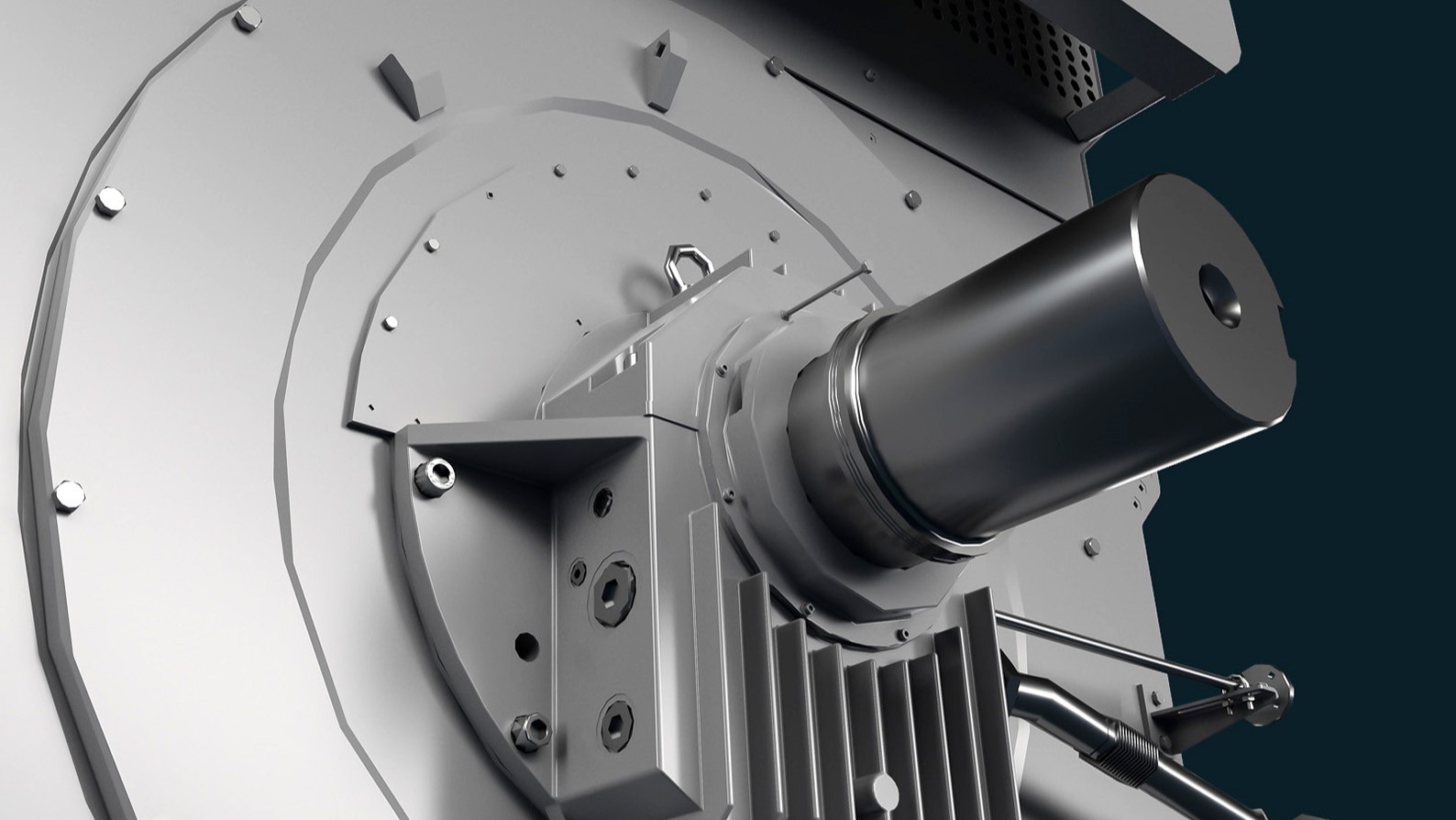

Repair Services for Motors

Services to keep your motors running at peak performance

Worldwide service for high-performance motors

Innomotics electric motors will power your processes reliably for decades - if they are operated within the right parameters and serviced regularly. Scheduled overhauls ensure that your motors always operate at peak efficiency. The interval between revisions varies depending on the workload and application of the motors.

Around the world, our repair centers and partner repair facilities are ready to assist you with technical support, on-site maintenance, revisions and repairs.

If the standard diagnosis of the cause of the failure is not sufficient for a repair, special investigations are performed to analyze the root cause and define the appropriate repair options. This way, you can always rely on optimal motor performance and maximum plant availability.

Your contact for personal support

To find your desired repair center, kindly select "Repair Centers & Service Partners" from the drop-down menu.

Your benefits at a glance

Our service offering to ensure optimum performance of your motors

World-wide service for high-performance motors

Innomotics electric motors are renowned for their quality, efficient operation and innovative features. They power your processes reliably for decades to come – if they are operated within the right parameters and maintained on a regular basis. Scheduled overhauls ensure that your motors are working at peak efficiency for years. The interval between revisions varies depending on the motors’ workload and the field of application. Around the globe, our repair shops and partner repair shops are ready to assist you with technical support, on-site maintenance, revisions and repairs in case of failure. So you can always rely on optimum performance of your motors and maximum plant availability. Contact us to get valuable maintenance recommendations for your motors!

- Inspection, measurement, checking, evaluation, documentation, consulting

- Maintenance on site or in the workshop including replacement of wearing and ageing parts as well as mechanical and electrical fault diagnosis

- Removal and installation of motors, laser-optical alignment, and commissioning

- Measurement of partial discharge, loss factors, and oscillations, thermography, frequency analysis

- Oil analysis, fault diagnostic, and special testing

- Special cleaning and drying processes

- Installation of condition monitoring systems for continuous recording of operating and condition data and trend recognition

- Repair of laminated stator and rotor cores, including rewinding

- Mechanical and electrical load tests and simulations

- Spare parts packages, spare-part supply and stock management

- Reconstruction and upgrades of electrical machines and components

Special Investigation

Sometimes the standard statement on the detected cause of error is not sufficiently for a repair. In this case there is the option to apply for a special investigation.

The special investigation is particularly suitable for root cause analysis of problems for the occurence of which no explanations have been found so far.

A special investigation is aimed at reproducing the problem, determining and communicating the cause of failure, as well as deriving sustainable measures from this.

The execution is usually performed by Innomotics.

Your benefit

- Identification of error causes.

- Reduction of expensive subsequent and repetitive errors.

- Full transparency for cost-intensive failures.